Heinen blizzard

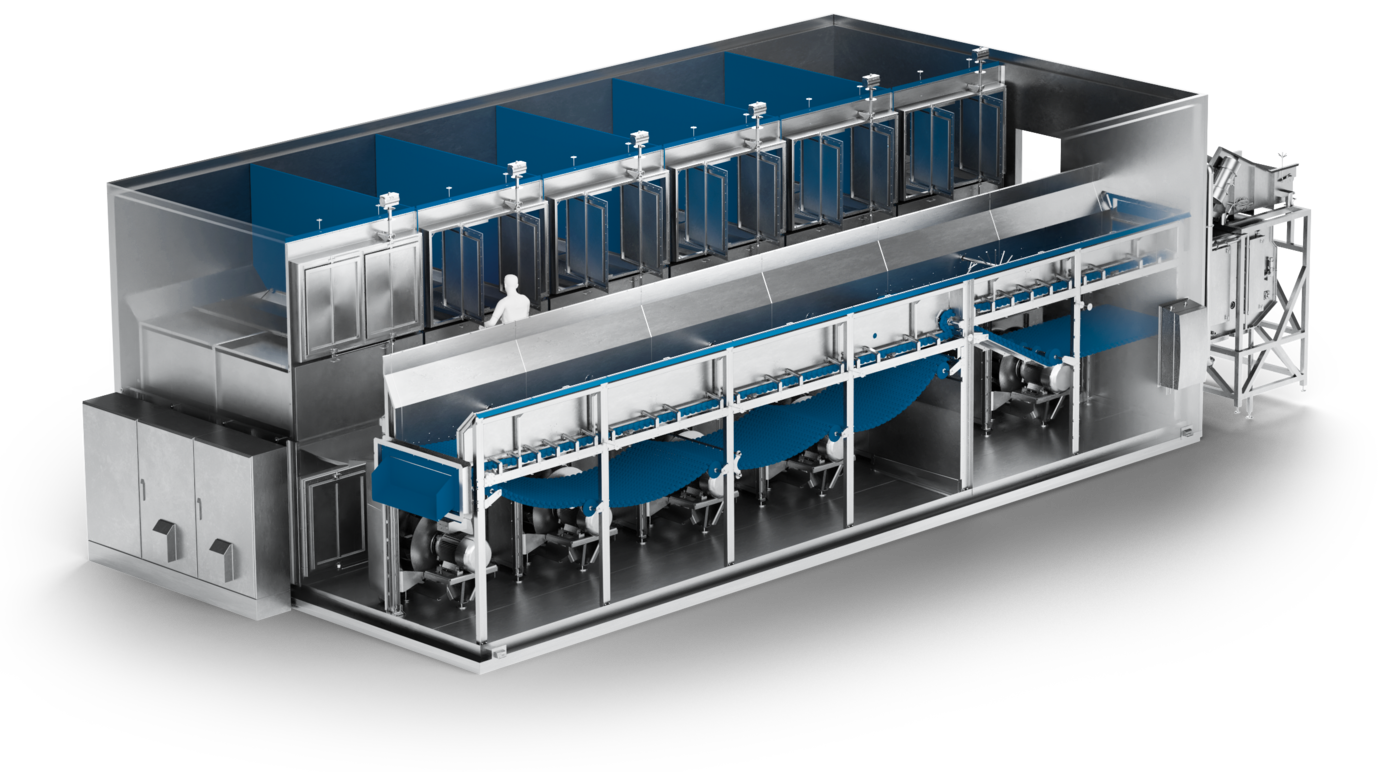

Freezing and cooling of bulk products with our blizzard. fluidized bed freezer. Fast but gentle freezing in the pre-freezing and primary freezing zone. For bulk products, such as diced meat, shrimp, mussels and other seafood, as well as peas and vegetables of all kinds, French fries or berries, at capacities of up to 15 tons/h (peas). Select from the various modules to find the capacity to suit your needs – we guarantee optimal performance.

- 01

- 01 Flexible

The different number of modules in the pre-freezing and main freezing zone and two system widths enable a tailored design exactly for the desired product and performance. Individually frequency-controlled drives for conveyor system and fans provide the flexibility necessary to handle different products in a single system.

- 02

- 02 Practical

Pre-assembled modules allow a fast installation as well as the installation in practically any production line arrangement. Installed on the floor, on a foundation, or on a frame, the blizzard is the ideal system for high and very high capacities.

- 03

- 03 Sophisticated

The wall and ceiling panels of the insulating enclosure are lined with stainless steel, while the floor is designed as a fully seam welded stainless steel tray with defined drains. The interior of the enclosure is accessed by means of three insulated stainless steel doors with contact switch and electric frame heating.

- 04

- 04 Reliable

The design for use in industrial multiple-shift operations, the ideal accessibility for cleaning, maintenance, and service, the use of high quality components, and the elimination of many moving parts guarantee the highest possible reliability.

- 05

- 05 Functional

The blizzard offers state-of-the art PLC controls, several remote service and communication options., programming and saving of all product and system parameters in recipes, plus elaborate visualization (3D images of the system, temperature trends, etc.) via colour touchscreen.

- 06

- 06 Efficient

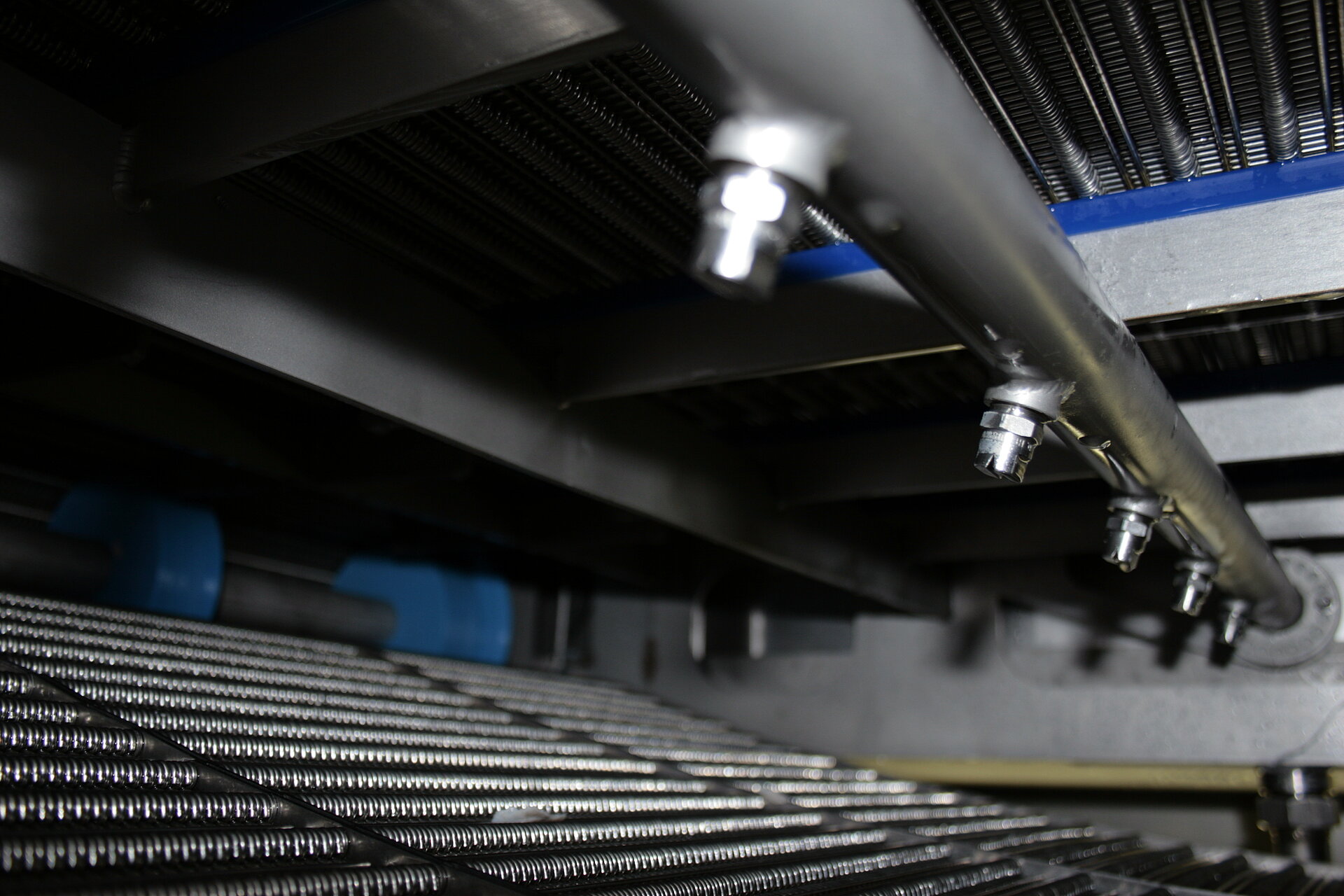

Air coolers made of stainless steel tubes and aluminium fins with large fin spacing ensure a low pressure loss. Sequential defrosting with different media such as hot gas, brine or electric heating elements provides continuous defrosting and enables production times up to 144h without interruption.

- 07

- 07 Modular

The simple belt cleaning system with a pump unit for increasing pressure generating foam can be progressively upgraded into an extended cleaning system or even further into an extended cleaning system that cleans besides the belt and conveyor system also the entire interior.

- 08

- 08 Versatile

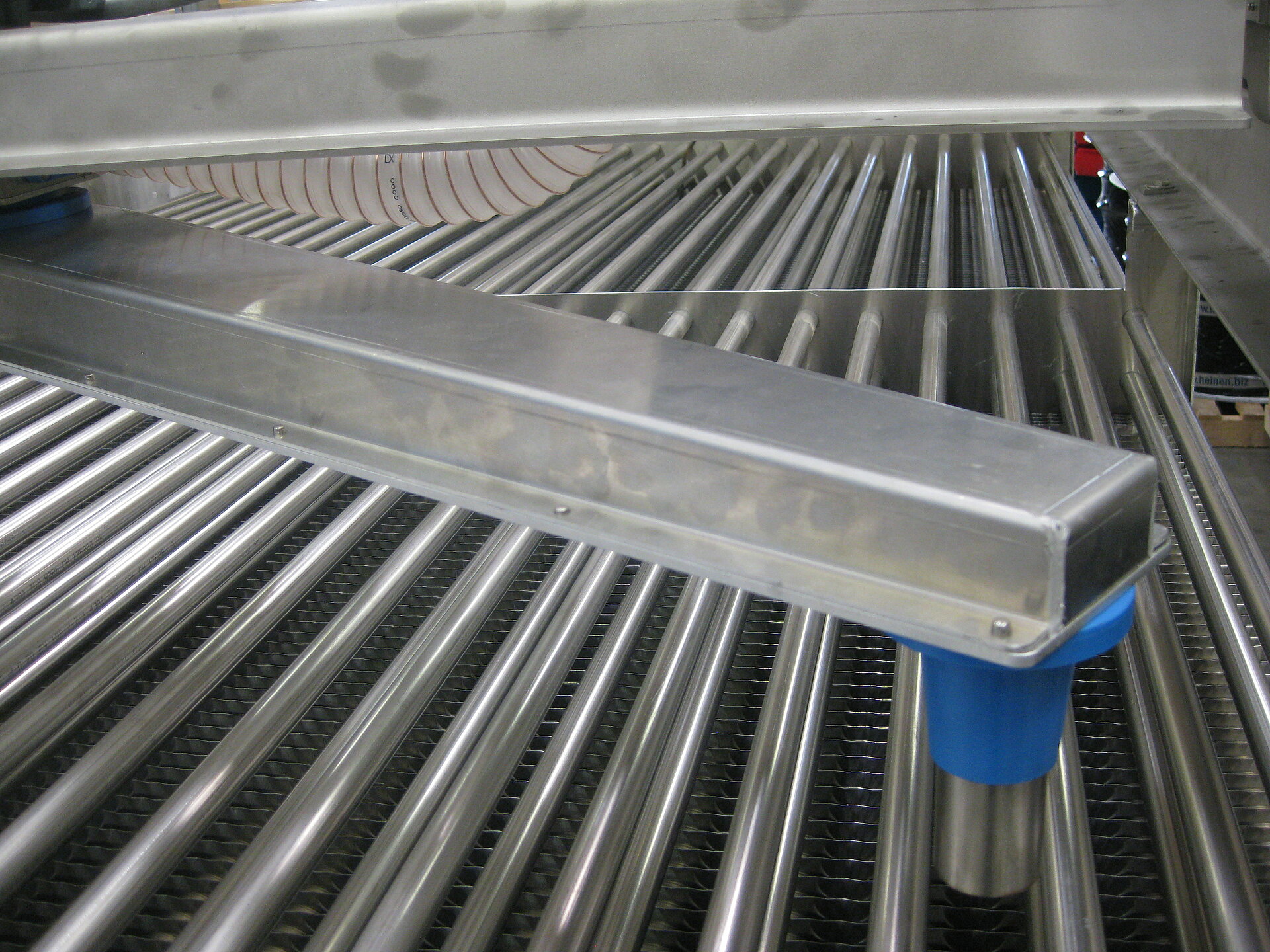

Light or heavy, soft or hard – every product is different. A variety of different belts made of stainless steel or plastic with different air circulation as well as the frequency controlled belt agitation and variable air volume control guarantee an optimum adaption to the product diversity.

- 09

- 09 Customised

The blizzard can be realised with numerous options, such as an insulating enclosure with a stainless steel exterior or a fully welded insulating enclosure, camera inspection, an extend infeed for continuous belt cleaning or a snow- and particle belt filter - custom designed to meet your needs.

Go into detail.

Here you can find a whole lot more information on our product.

Heinen blizzard

product specification sheet

Get in

contact.

You still haven’t learned enough on this website? Feel free to contact us.