Heinen: German engineering from a to z.

From the first sketches through design, construction, testing, delivery, installation, programming and maintenance – Heinen truly stands for german engineering in each and every step. And that is how we meet our customers needs, regardless of whether it comes to pasteurizing, proofing, cooling or freezing of almost any food. Our philosophy in just a few words? We are not thinking in terms of problems, we're thinking in terms of solutions. That's why we say: "Heinen. Mastering any degree."

Markus Decker

Sales

From -35 to +95 °C.

Here's how to master any degree.

Pasteurizing, proofing, cooling or freezing, – pizza, meat or almost any other food: Here you can easily discover the whole range of Heinen solutions. Choose from food and/or process. And if you don't find a solution – we'll invent one for you.

Your product

Choose your product by scrolling the wheel.

Your process

Choose your process. You can either choose a single process or a process line, e.g. proofing/freezing, by clicking on it.

Our solutions

Here you can find the right Heinen solution for your product and/or your process.

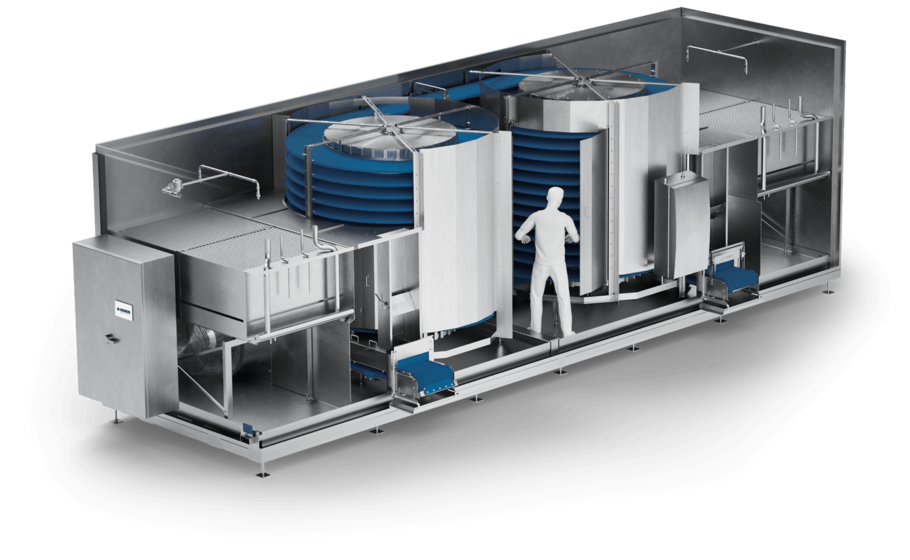

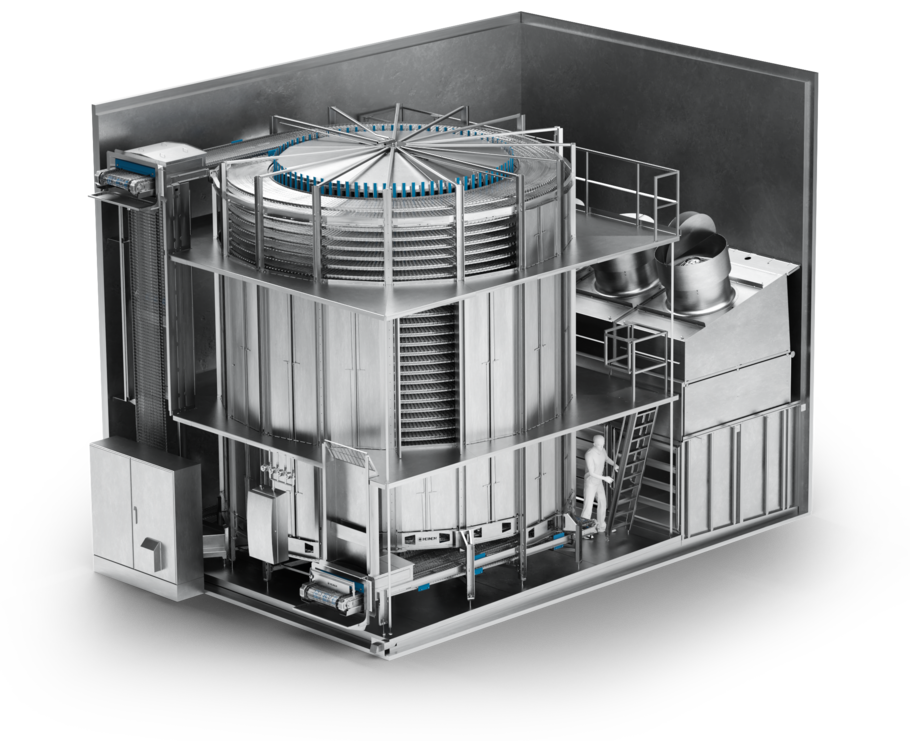

For your start-up in frozen food production or the production of specialty items, we’ve exploited the experience gained from our large-scale industrial plants in the development of this system. A compact solution realized for freezing and cooling in the medium-capacity range with a minimum of available space.

For your start-up in frozen food production or the production of specialty items, we’ve exploited the experience gained from our large-scale industrial plants in the development of this system. A compact solution realized for freezing and cooling in the medium-capacity range with a minimum of available space.

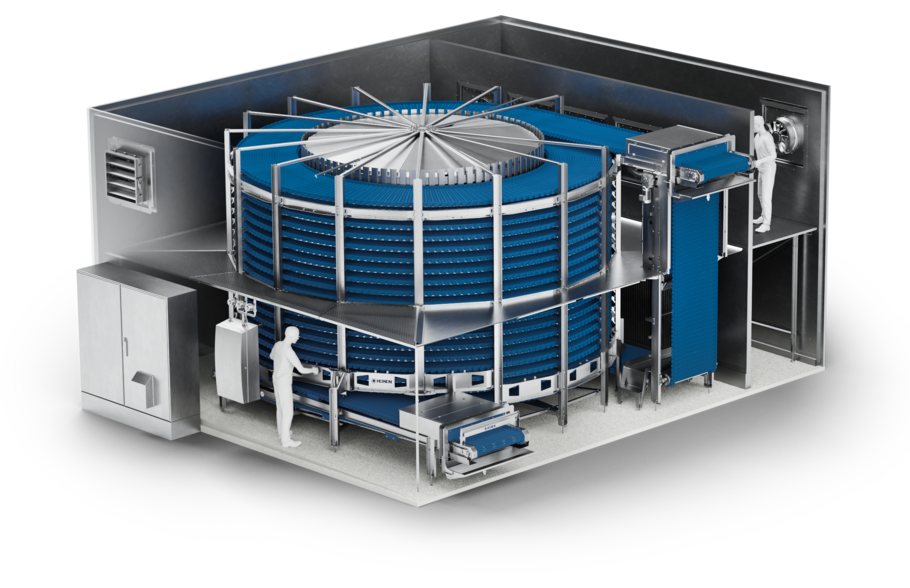

The “multi-talent” flexible and versatile spiral system for cooling and freezing of all kind of food products with various belt widths and tier pitches as single or double drum plus numerous options for medium and high capacities.

The "basic-system" – flexible and versatile spiral system for conveying and ambient air cooling with various belt widths and tier pitches, as single or double drum as well as numerous layouts and options for medium and high capacities.

The “soft” – spiral system with climate control for active cooling of bakery products, various belt widths and tier pitches as single or double drum plus numerous options for medium and high capacities.

Spiral fermenter for fermenting and cooling with climate control. The climate is always fine in the proofline spiral fermenter. Extra gentle treatment of the product with perfectly coordinated resting, fermenting and cooling phases in combination with the advantages of a continuously operating spiral system. Customized to meet the particular requirements of your product’s fermentation process. Long retention times and flexible and precise climate conditions for a multitude of products have turned this machine into one of the most frequently used systems in the industrial production of baked goods.

The hot spiral system with dry or moist air and precision climate control as a single or twin-tower model for medium-sized to large capacities.

For your start-up in the production of frozen food our compact and modular fluidized bed system for cooling and freezing of bulk products as single or two-belt system with one belt width, in three capacities for small to medium productions.

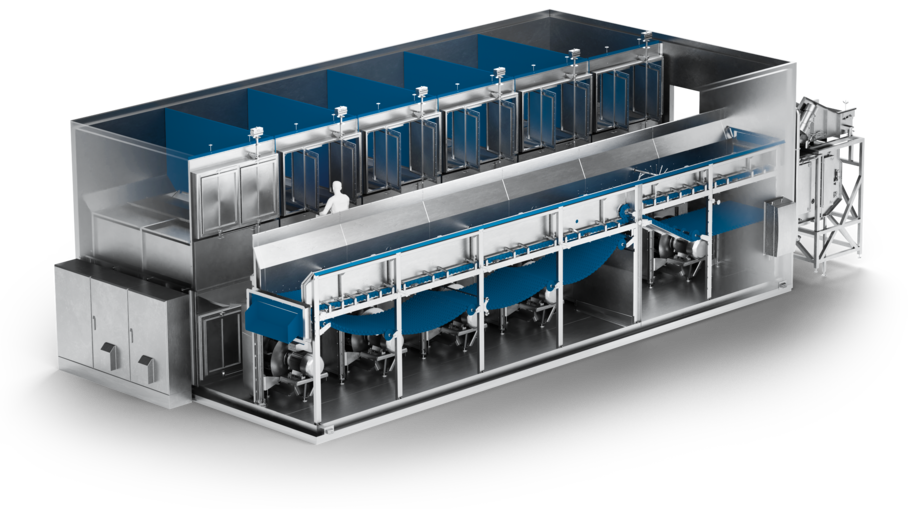

Freezing and cooling of bulk products with our blizzard fluidized bed freezer. Fast but gentle freezing in the pre-freezing and primary freezing zone. For bulk products, such as diced meat, shrimp, mussels and other seafood, as well as peas and vegetables of all kinds, French fries or berries, at capacities of up to 15 tons/h (peas). Select from the various modules to find the capacity to suit your needs – we guarantee optimal performance.

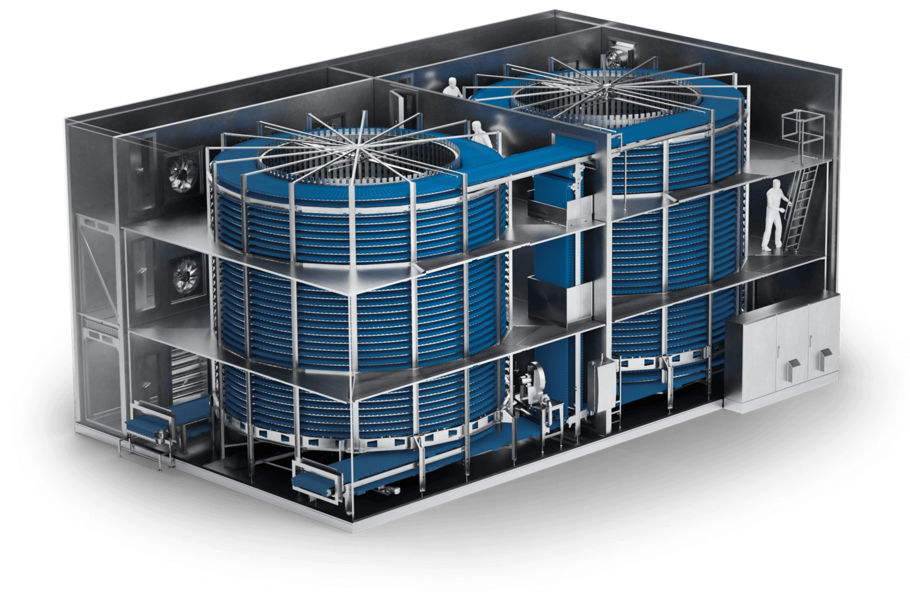

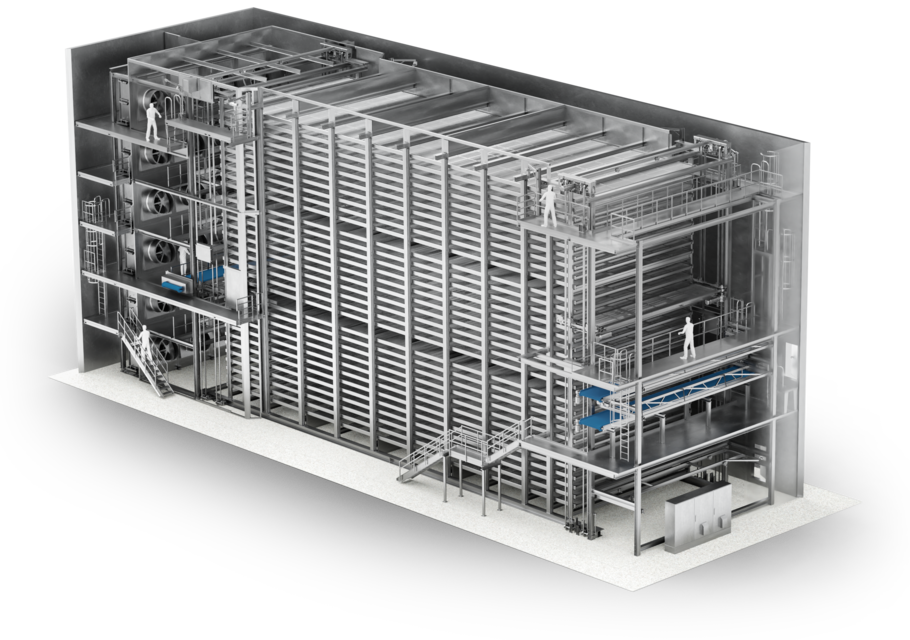

Our largest system – the modular multilevel box freezer for cooling and freezing of goods packaged in cartons or plastic boxes in two system widths with various number of levels and numerous options for high capacities.

At your service.

Anything you need to keep things going.

Because the quality of Heinen products grant a lifespan of multiple decades, our service plays a very important role within the Heinen identity. We know, production does not only take place during business hours – that's why we offer a 24/7-service. We do not only sell products – we deliver solutions that work. Our service range? Inspections, repair, spare parts, remote service, retrofits & relocations, training and service level agreements.