Heinen freezelite®

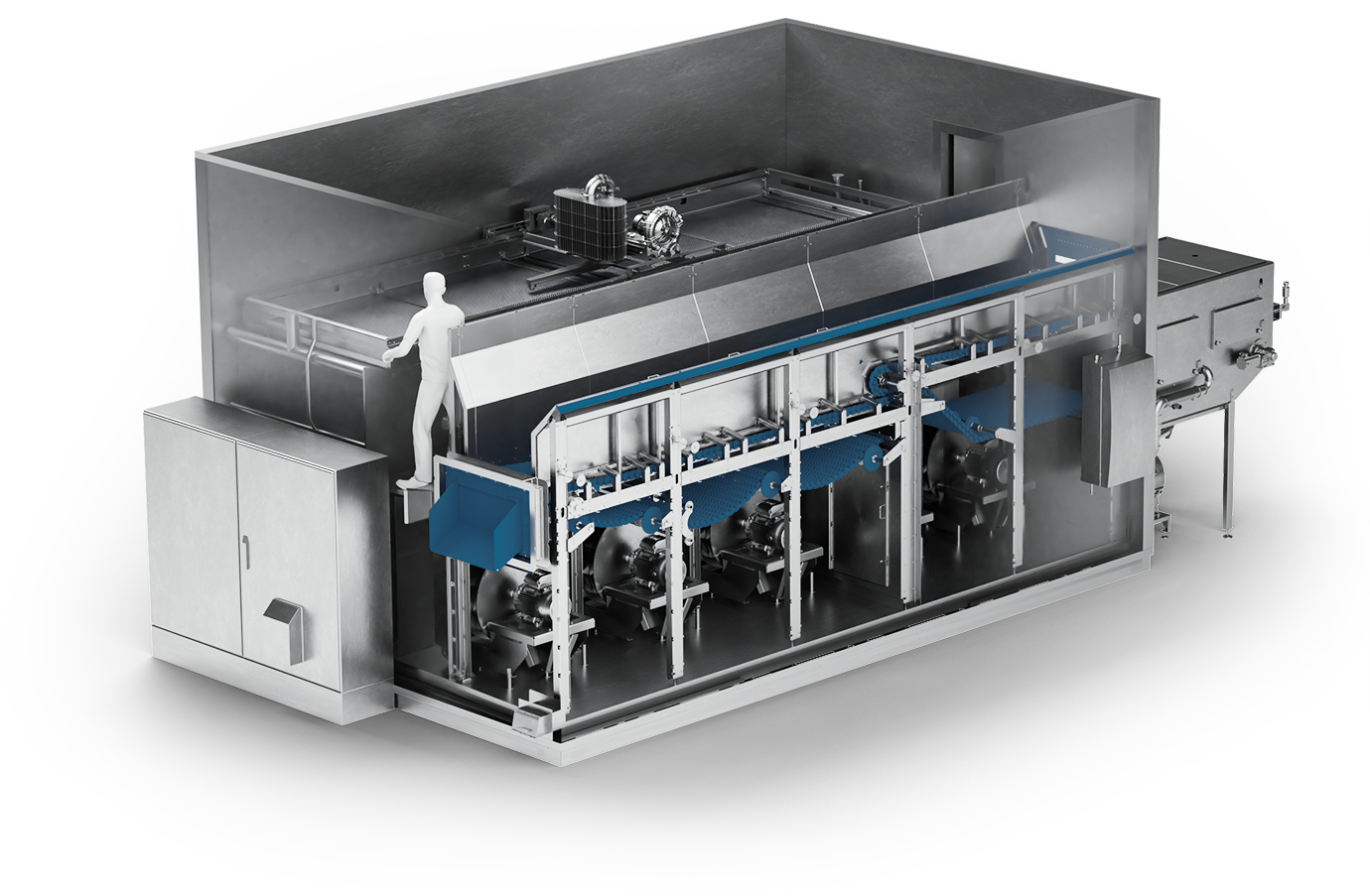

For your start-up in the production of frozen food our compact and modular fluidized bed system for cooling and freezing of bulk products as single or two-belt system with one belt width, in three capacities for small to medium productions.

- 01

- 01 Modular concept

Due to the different number of modules in the pre-freezing and main freezing zone as well as two different belt-widths, the system can be designed exactly for product and performance as well as adapted to local conditions. Performances from 1,500 kg/h up to 7,500 kg/h (based on green peas) are thus possible.

- 02

- 02 Quick installation

The system is completely pre-assembled and tested in the factory. For transport, it is unfastened into individual modules and then finally assembled on site on a foundation or on machine feet in a few days. After short commissioning and training, the system is ready for production immediately.

- 03

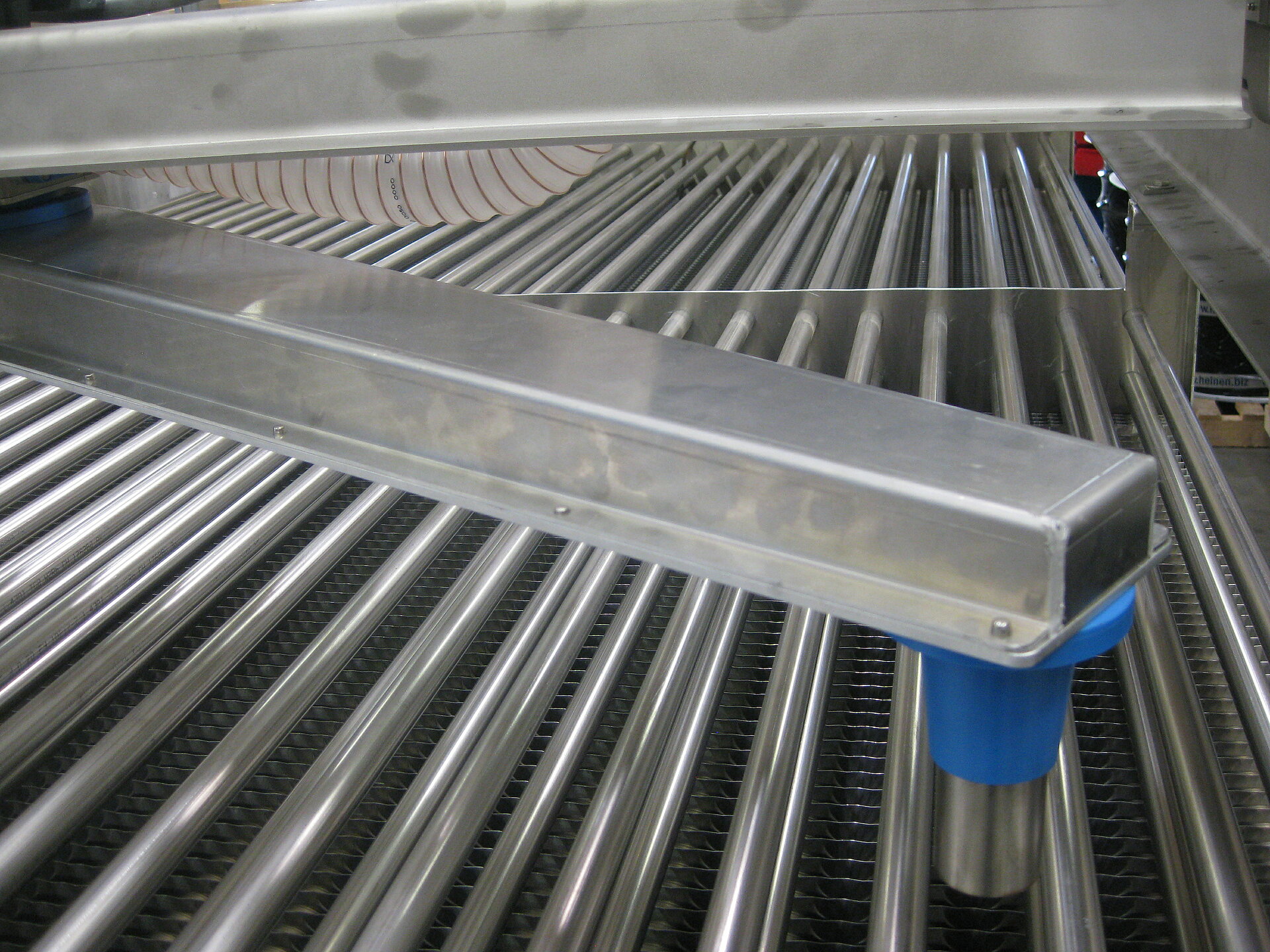

- 03 Hygienic design

The insulating floor and the insulating walls are fully welded inside. The floor area is designed with slope and extra large drains. The system is fully accessible for cleaning and is built in hygienic design out of laser cut stainless steel and plastic components.

- 04

- 04 High availability

The use of elements from proven manufacturers such as SEW and Siemens, the heavy industrial design as well as the basic solid workmanship lead to a high availability. The system is designed for continuous load and a long lifetime.

- 05

- 05 Innovative comfort

The system is operated via a colour touch panel with extensive visualization (3D system images, temperature trending, etc.). A communication interface, a remote maintenance connection and the intuitive menu navigation for fault handling as well as for maintenance and service work offers innovation and comfort in equal measure

- 06

- 06 Low costs

All drives are designed in the energy efficiency class IE3 and are controlled by frequency inverters. The flow-optimized air flow and the installation of air coolers with large air inlet surface reduce pressure losses and ensure low energy consumption.

- 07

- 07 Best cleanability

The "hygienic design" and the tool-free disassembling of the frequently cleaned system components allow for effective cleaning. The optional automatic cleaning system with freezer foamer or satellite unit for cleaning the conveyor belts, air coolers and other important plant areas reduces the necessary cleaning time.

- 08

- 08 Flexible use

For the production and cleaning mode, all product, process and plant parameters can be stored in recipes and thus enable quick switching. With numerous options, such as pulsation flaps, agitation mode for the conveyor belt or the snow blow-off system, the application possibilities of the system can be extended.

- 09

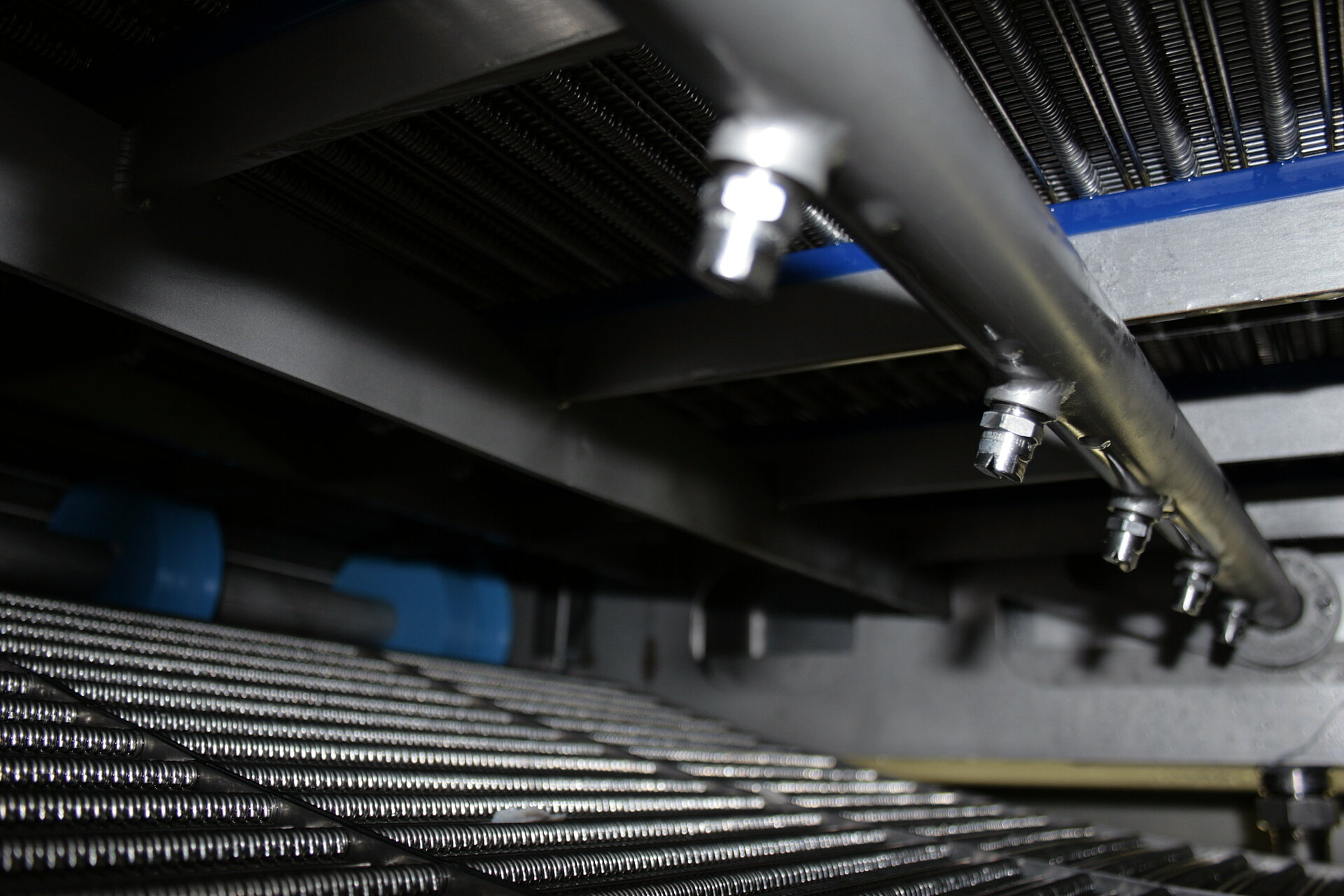

- 09 Long operable

The freezelite has air coolers made of stainless steel tubes with aluminium fins and large fin spacing. The snow blow-off system makes it possible to continuously blow off the fins with air out of the system. With an externally extended infeed, it is possible to wash and dry the belt while the system is still cold, for a virtually continuous operation.

Go into detail.

Here you can find a whole lot more information on our product.

Heinen freezelite®

product specification sheet

Get in

contact.

You still haven’t learned enough on this website? Feel free to contact us.