Heinen proofline®

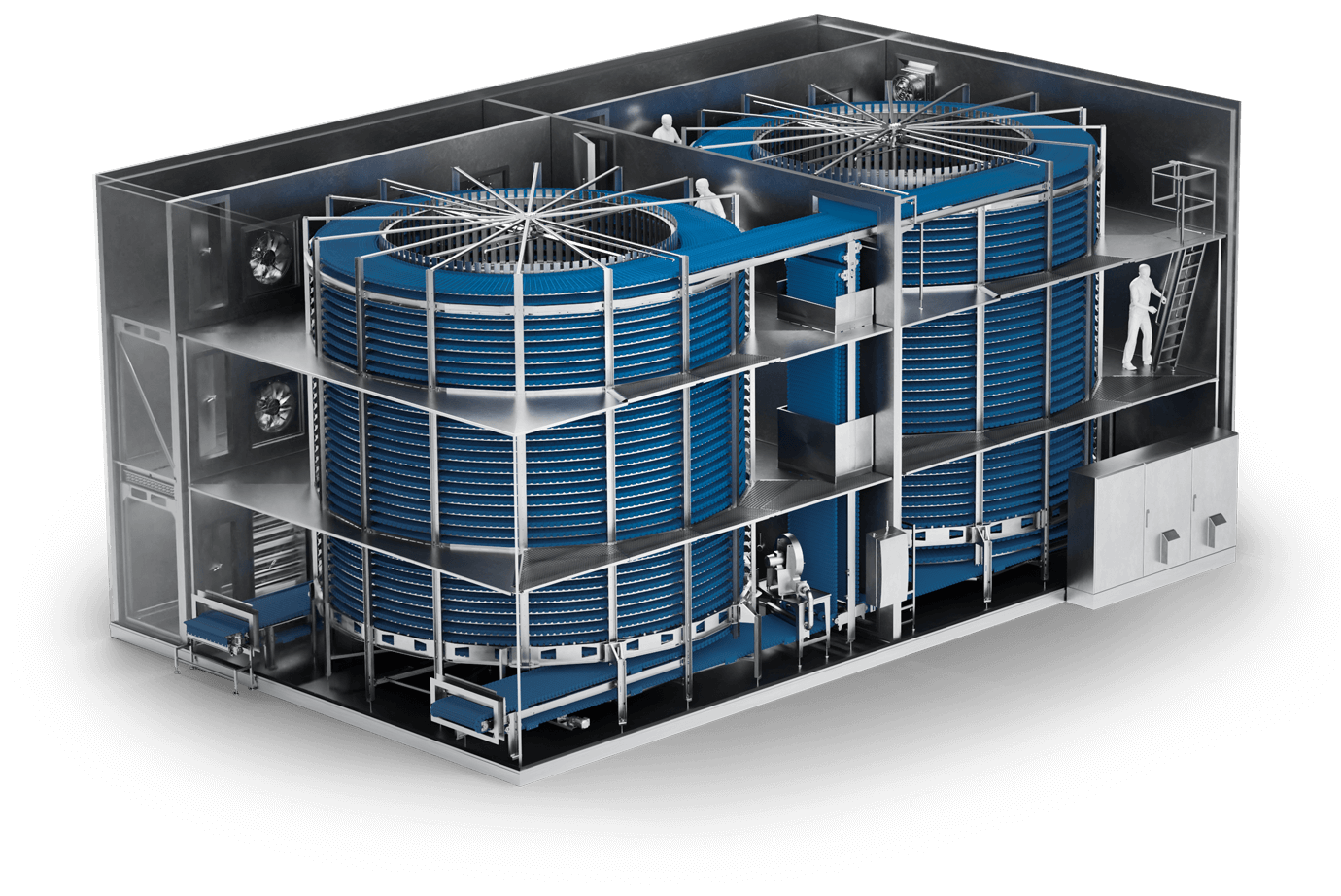

Spiral fermenter for fermenting and cooling with climate control. The climate is always fine in the proofline spiral fermenter. Extra gentle treatment of the product with perfectly coordinated resting, fermenting and cooling phases in combination with the advantages of a continuously operating spiral system. Customized to meet the particular requirements of your product’s fermentation process. Long retention times and flexible and precise climate conditions for a multitude of products have turned this machine into one of the most frequently used systems in the industrial production of baked goods.

- 01

- 01 Flexible

As single or double tower, upwards and downwards conveying, with four layout options and three system diameters; placed on the factory floor, foundation, or a subframe, proofline fulfills nearly all requirements in terms of capacity and integration processing and building.

- 02

- 02 Versatile

Depending on the variety of product and processing, proofline can work with a proofing zone, with a proofing and cooling zone or also can be configured as a three-zone proofing plant with relaxing, proofing and cooling zones. The relaxing zone can be operated as a relaxing zone or as additional pre-proofing zone.

- 03

- 03 Sophisticated

Wall and ceiling panels of the insulating enclosure have a stainless steel interior and the floor is designed as a welded stainless steel tray with defined drains. Access by means of an insulated stainless steel door with contact switch.

- 04

- 04 Reliable

Designed for industrial multi-shift applications, the highest degree of reliability is guaranteed by the smooth belt guidance via drum and frequency-controlled main drive and overdrive motors, the use of high-quality components, and the minimum of moving parts.

- 05

- 05 Functional

The proofline offers state-of-the-art PLC controls, several remote service and communication options, programming and saving of all product and system parameters in recipes, plus elaborate visualization (3D images of the system, temperature trends, etc.) on a colour touchscreen.

- 06

- 06 Accurate

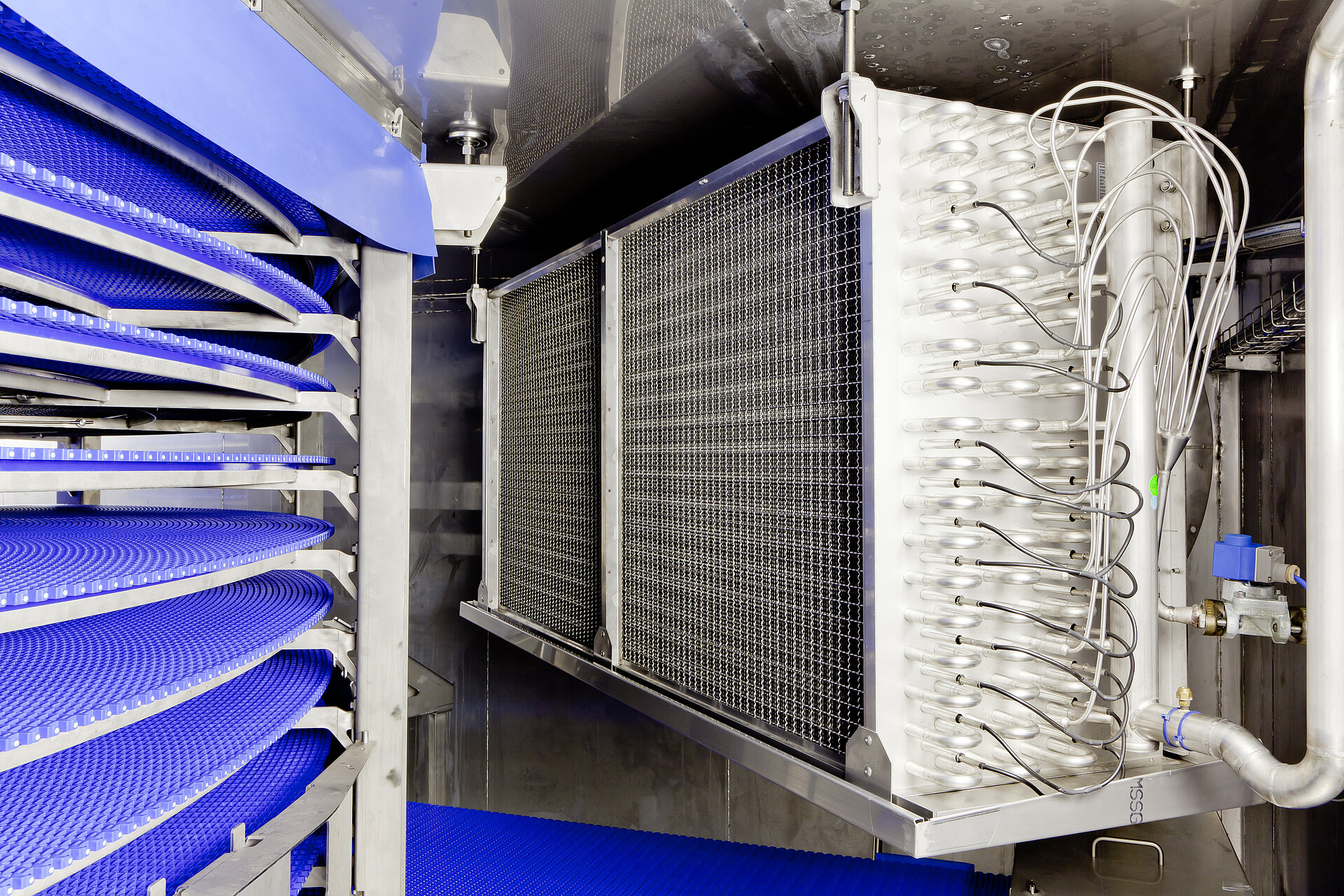

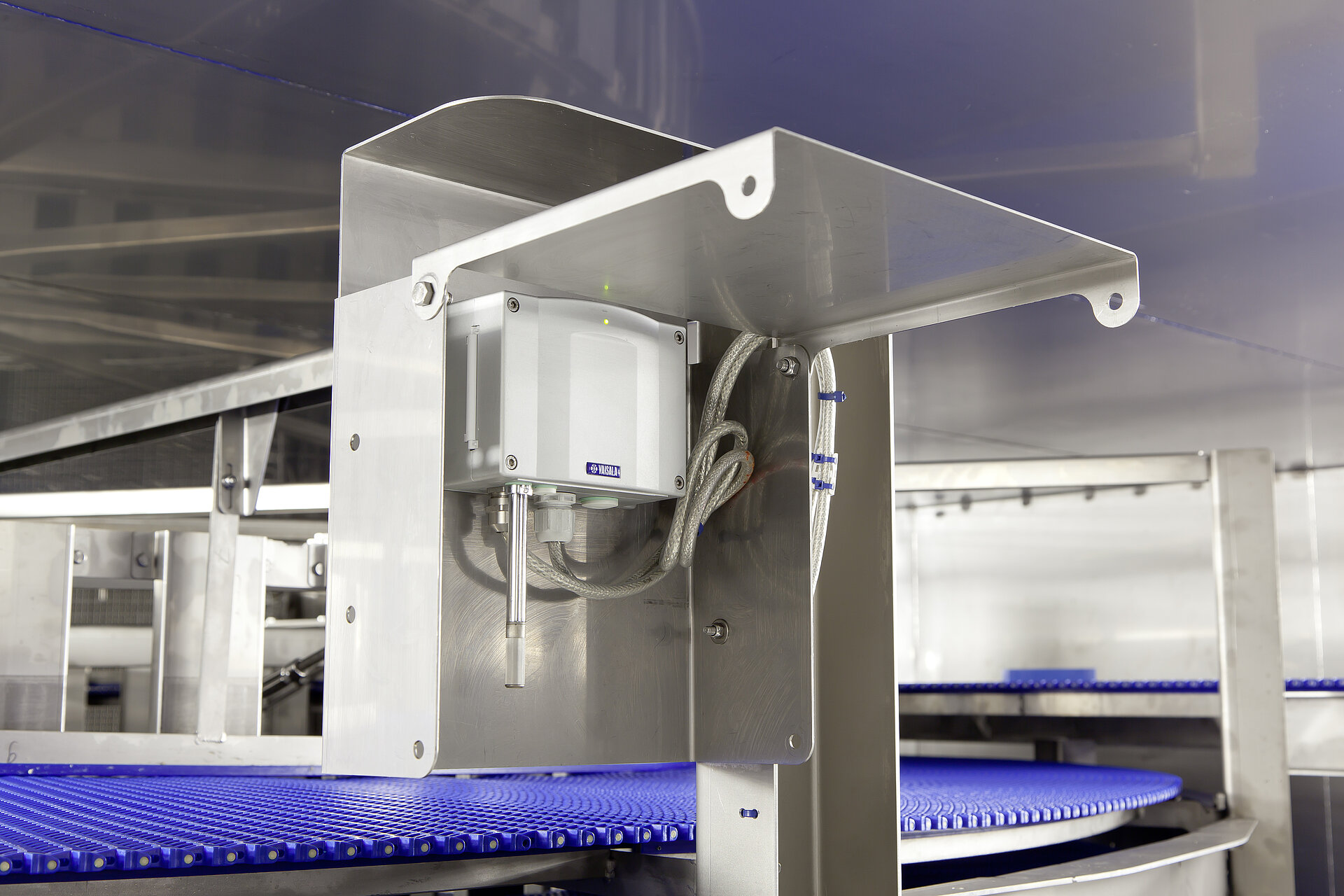

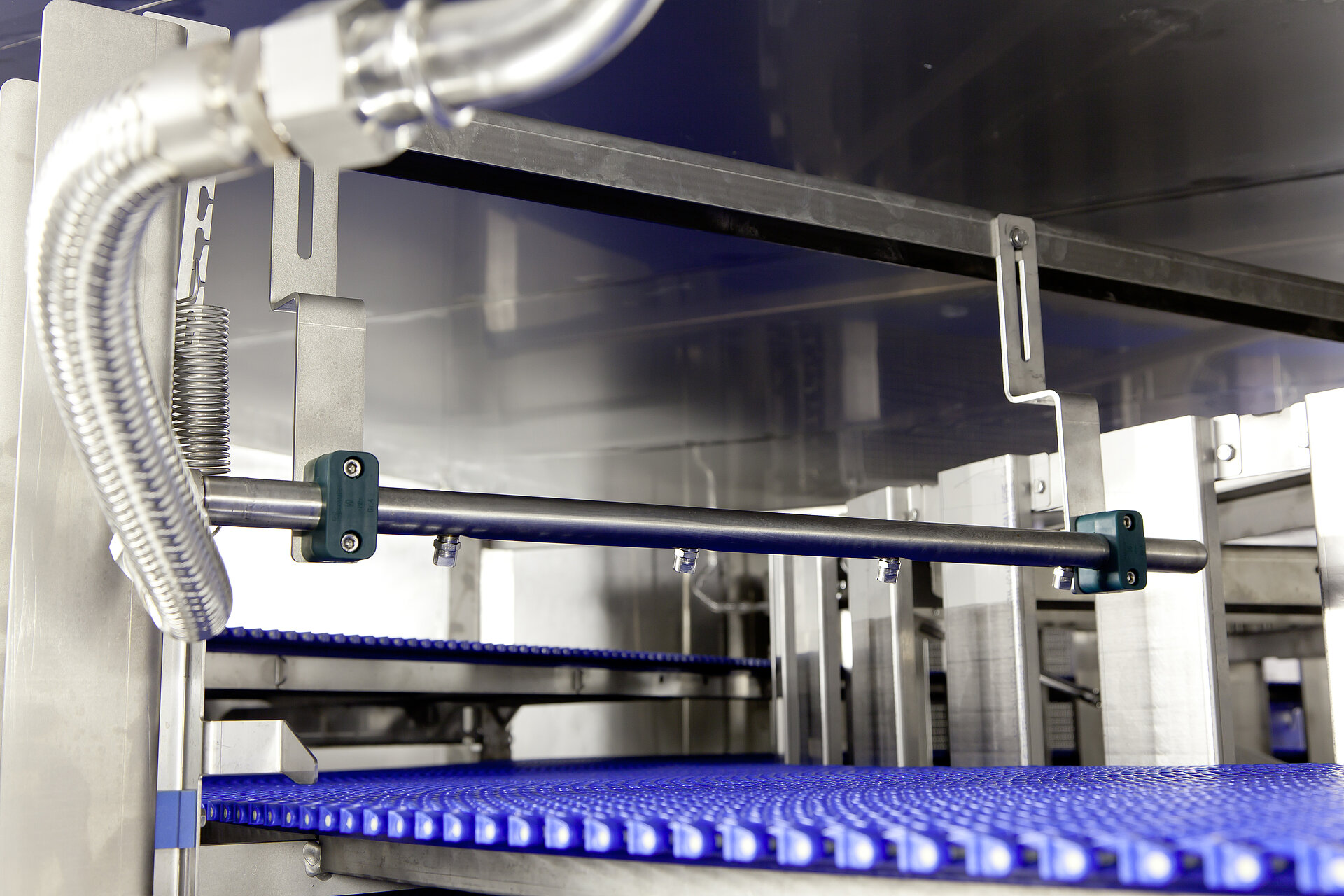

proofline achieves extremely precise fermentation conditions with a continuous process of air dehumidification, humidification and heating with very low air speeds caused by a division of the total air flow into small streams of air; this in addition to air conveyance via frequency-controlled fans.

- 07

- 07 Modular

The simple belt cleaning system, with a pump unit for increasing pressure generating foam can be progressively upgraded into an extended cleaning system or even further into a fully integrated cleaning system that cleans the entire interior in addition to the belt and the conveyor system.

- 08

- 08 Special

With the loading conveyor for the transfer of products onto the already collapsed belt, which can be designed with up to four individually driven tracks as well as with individually driven transfer shafts, the proofline is particularly suitable for high-quality dough products.

- 09

- 09 Customised

The proofline can be realised with numerous options such as an insulating enclosure with a stainless steel exterior or a fully welded insulating enclosure, ultrasonic or high pressure humidification; with integrated bypass, and performed in asymmetrical layouts – custom-designed to meet your needs.

Go into detail.

Here you can find a whole lot more information on our product.

Heinen proofline®

product specification sheet

Get in

contact.

You still haven’t learned enough on this website? Feel free to contact us.